The Just in Time Inventory System Focuses on Minimizing

With growing competition and increasing pressure to boost profitability many businesses have adopted this strategy to boost their bottom linewhich can be problematic. Just in time JIT inventory is a strategy to increase efficiency and decrease waste by receiving goods only as they are needed in the production process thereby reducing inventory costs.

.jpg)

The Benefits Of Just In Time Inventory Manufacturingtomorrow

A Just-in-Time JIT inventory management program has all but which of the following requirements.

/inventory-291c7c3c45a74e0a94c3708742e48ff9.jpg)

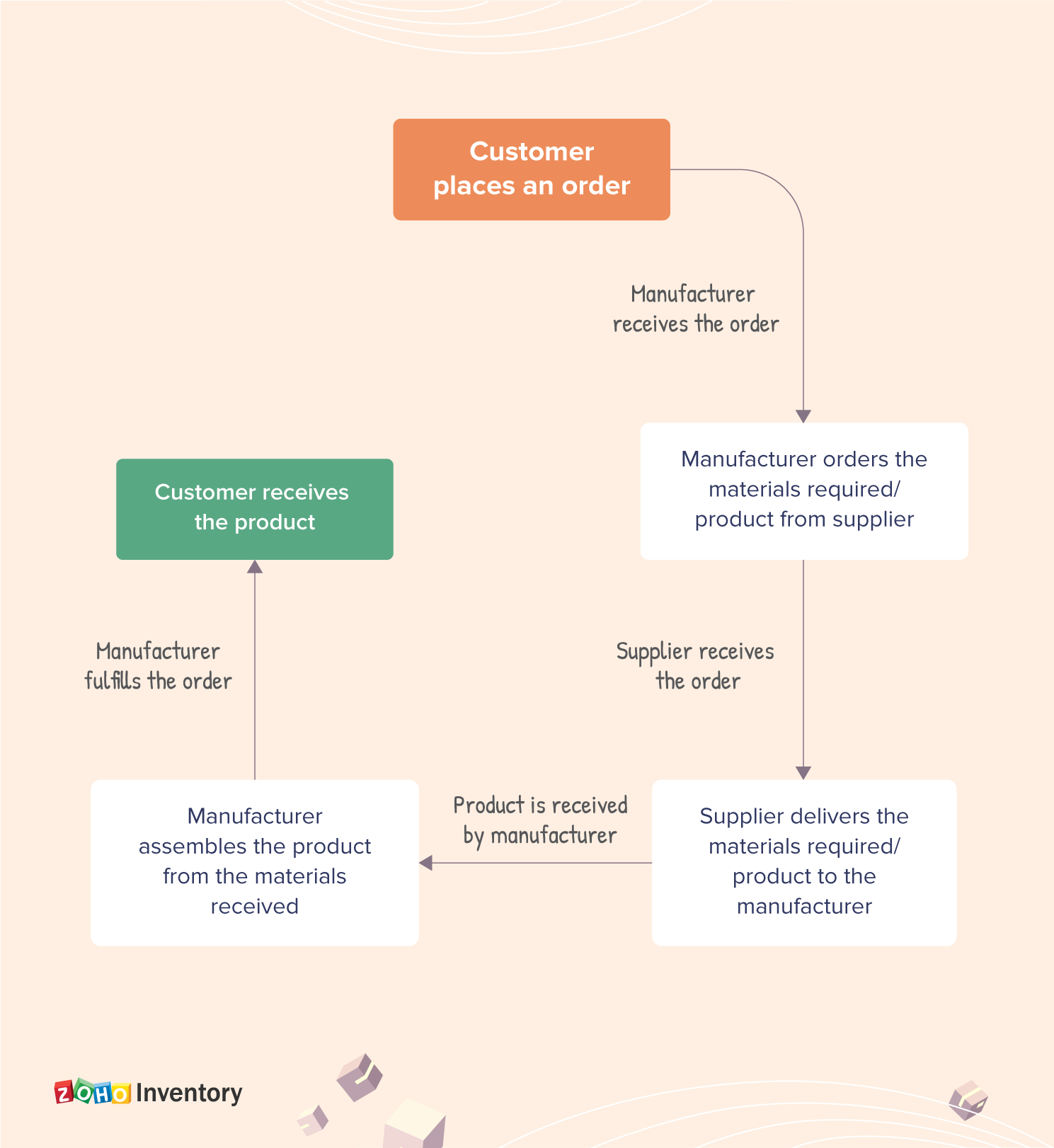

. In a nutshell JIT means that a product is only ordered or manufactured once an order has been placed. The goal of a JIT system is to receive new products just as theyre neededany sooner and youll have. Harley-Davidson employs a method of inventory control demanding that suppliers deliver parts and raw materials to Harleys production facility just as.

Just-in-time JIT is a production technique that was first pioneered by Toyota to minimize the need for excess inventory through linking production to demand. Just-in-time JIT inventory and just-in-time manufacturing have been buzzwords in the world of supply chain for some time now and quite a few businesses have adopted this approach. Just-in-time JIT is a management approach that is used to control the flow of inventory to and from a business in order to minimize inventory levels and to improve the efficiency of the manufacturing processes.

Just-in-time inventory benefits those with efficient operations and is good for the bottom line. On-demand publishing is a prime example of the JIT inventory method and it has become popular with independent publishers and self-publishing businesses. View the full answer.

Better cash flow less cost of operation flexibility and higher efficiency can significantly improve your companys bottom line. The just-in-time JIT inventory system was developed to support the excellent production movement of the Toyota Motor Company. That means you dont stockpile products and raw materials just in case you need themyou simply reorder products to replace those youve already sold.

Reduce waste while increasing quality assurance. Storage and holding costs. Just-in-time JIT manufacturing is also known as the Toyota Production System TPS because the car manufacturer Toyota adopted the system in the 1970s.

Just-in-time inventory benefits those with efficient operations and is good for the bottom line. The just-in-time JIT inventory system is a management strategy that minimizes inventory and increases efficiency. And in the right place as per the demand.

Multiple Choice Quality production Large safety stocks Close ties between suppliers manufacturers. Just-in-time inventory is an effective inventory management system used globally. Just-in-time JIT inventory management also know as lean manufacturing and sometimes referred to as the Toyota production system TPS is an inventory strategy that.

The just-in-time inventory system focuses on minimizing a. The _____ is awarded for outstanding in specific managerial tasks. Just-in-time inventory method refers to having the inventory readily available at the right time.

Manufacturers are also not left with unwanted inventory if an order is ca. The just-in-time method trims operational waste by only supplying exactly whats needed for use. Storage and holding costs.

This article explains how a firm manages her inventory to gain minimum production cost and earn business success by using Just in Time JIT Manufacturing System. A benefit that often accompanies this level of insight and control is improved product quality. Just-in-time inventory offers you the flexibility to stop ordering products that dont sell and focus on ones that do.

Large safety stocks Explanation Just-In-Time is an inventory managemen. B materials resource planning. JIT production systems cut inventory costs because manufacturers receive materials and parts as needed for production and do not have to pay storage costs.

Being proactive with just-in-time management saves you the headache of overseeing more than you need to. It helps in minimizing overstock and hence save space while optimizing inventory. It utilizes the advancement of software technologies to simplify and optimize the supply chain system order processing production stocking and delivery by scheduling the required stock only at the right time to meet the demand without incurring inventory handling and holding costs.

Just-in-time inventory management optimizes the supply chain but there are caveats. Just-in-time inventory management optimizes the supply chain but there are caveats. This strategy also prevents overproduction and minimizes transport costs.

The just-in-time inventory system focuses on minimizing A. Materials resource planning C. The strategy is to arrange the orders of raw materials in such a way that the goods are only ordered when required for production.

This strategy also prevents overproduction and minimizes transport costs. JIT production systems cut inventory costs because manufacturers do not have to pay storage. Computerized inventory management B.

Just-in-time or JIT is an inventory management method in which you keep as little inventory on hand as possible. The just-in-time inventory system focuses on minimizing a. E E storage and holding costs.

Storage and holding costs. The just - in - time inventory system focuses on minimizing. He went on to describe just-in-time as a more lasting possibility of major cost reduction citing the potential for reducing cash tied up in.

View the full answer. Just-in-time record keeping. E storage and holding costs.

The delivery of raw materials is scheduled based on production needs such as the. The idea is to receive production inputs only as needed in the production process. Storage and holding costs.

The just in time inventory system or JIT is a system of managing inventory that is designed to improve efficiency and reduce waste in a production process and minimize inventory carrying costs. 100 11 ratings Ans. The overall goal of the system is to strictly control the purchase and delivery of raw materials to minimize storage inventory and fixed costs.

The just-in-timeJIT inventory system minimizes inventory and increases efficiency. The just-in-time inventory system focuses on minimizing A scheduling.

Just In Time Reduce Waste Improve Your Production Tulip

Pull Production System Kanban Lean Six Sigma Lean Manufacturing

No comments for "The Just in Time Inventory System Focuses on Minimizing"

Post a Comment